- 86-577-86932718

- info@tigermold.com

- No.331, Wenzhou, Zhejiang, China

Ejector pins are an essential component in the injection molding process, playing a crucial role in the efficient removal of molded parts from the mold cavity.

These precision-engineered pins help push the molded item out of the mold once it has cooled and solidified, ensuring smooth, accurate, and timely production.

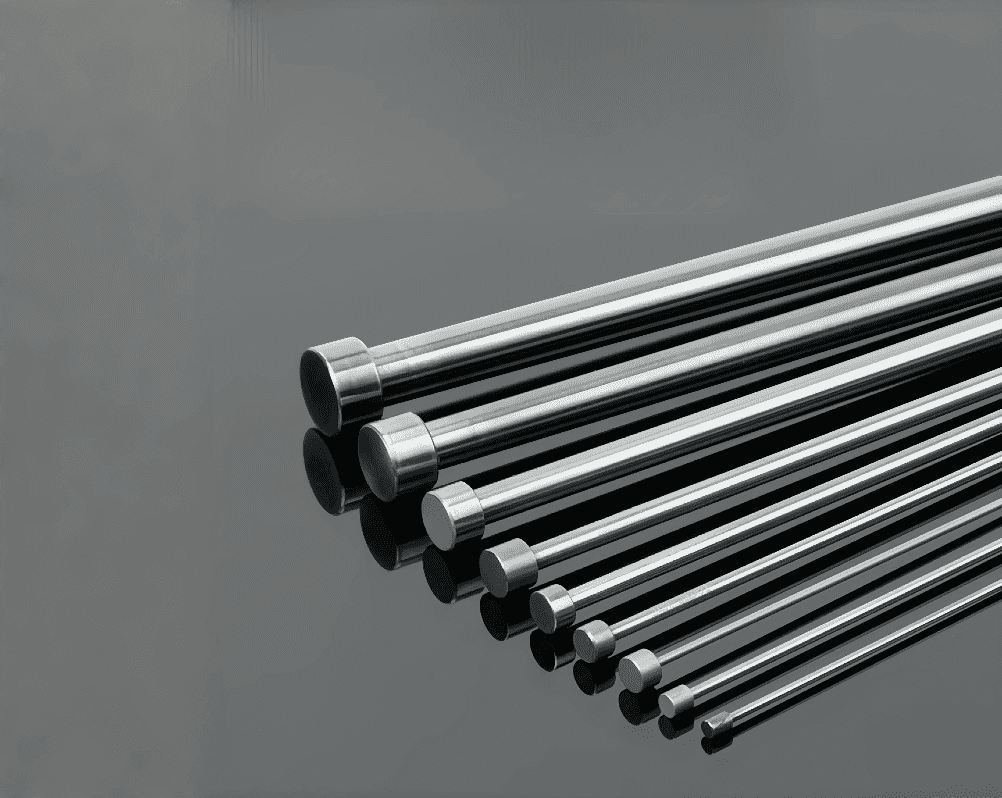

Ejector pins are metal rods, typically made of high-quality steel or stainless steel, designed to be inserted into an injection mold.

When the mold opens, the ejector pins push the molded part out, preventing any damage or defects caused by manual removal. They are used in various mold designs and applications, ensuring high precision and reliability.

Our ejector pins are manufactured with tolerances as tight as ±0.005mm to ±0.02mm, depending on the specific requirements of the application.

This level of precision ensures that each pin fits perfectly within the mold, promoting smooth ejection without distortion or damage to the molded parts.

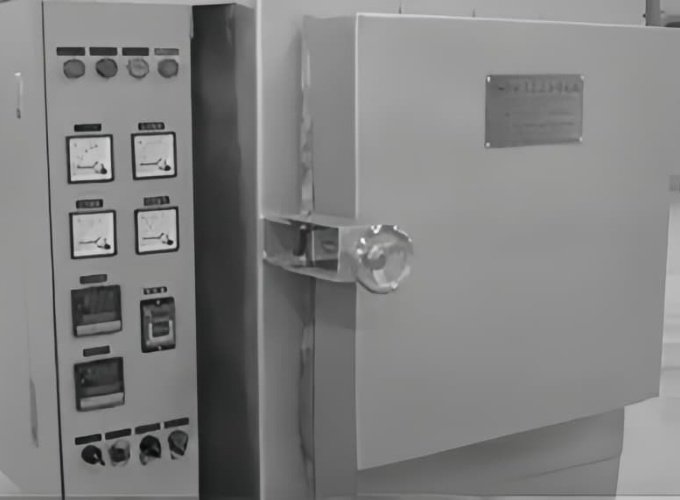

Our ejector pins are typically made from high-strength steel alloys, such as H13 or SKD11, which are known for their excellent wear resistance and durability. Through precise heat treatment processes, including quenching and tempering, we are able to achieve the required hardness levels for different applications.

The typical hardness of our ejector pins ranges between HRC 48 to HRC 55 (Rockwell Hardness Scale), depending on the material used and the specific requirements of the application.

The material used for the ejector pin must be compatible with the material being molded. Ejector pins are typically made from high-quality steel alloys like H13 or SKD11 due to their excellent hardness and wear resistance.

The size and length of the ejector pin are crucial for ensuring proper part ejection without causing distortion. The length should be sufficient to ensure the pin can effectively push the part out of the mold cavity once it has solidified.

A smooth surface ensures minimal friction, allowing the ejector pin to move freely within the mold without excessive wear. Additionally, surface treatments such as polishing, nitriding, and chrome plating can further improve the pin's performance and longevity.

The tip needs to be designed to fit the shape of the molded part to ensure smooth and damage-free ejection. Flat or Pointed Tips and Tip Geometry.

For high-volume production, you may require ejector pins that can handle increased stress and wear, so selecting pins with higher hardness (e.g., HRC 50-55) and additional treatments is essential.

Pins with greater strength and hardness will resist bending or breaking under the pressure exerted during the ejection process.

Ejector pins are a fundamental component of the injection molding process, designed to push molded parts out of the mold cavity once the plastic has cooled and solidified.

Once activated, the ejector pins extend outward from the mold’s cavity or core, pushing against the molded part. The pins apply a controlled force to the part to release it from the mold without damaging its structure.

The ejector pins work together with the mold’s opening mechanism to ensure smooth, accurate ejection.

We thoroughly inspect all incoming raw materials to ensure they meet our strict quality standards before production begins.

Our team conducts regular checks during production to monitor consistency, precision, and adherence to design specifications.

Our team conducts regular checks during production to monitor consistency, precision, and adherence to design specifications.

Before shipment, we perform a final inspection to guarantee that all products meet quality requirements and are ready for delivery.

At Tiger Mold, we simplify your procurement process with a vast inventory of ejector pins and mold components. With our one-stop service, you get everything you need in one place, saving you time, effort, and costs.

The 10-15 day lead time for customized products allows us to ensure precision in manufacturing, complete any required adjustments, and perform thorough quality checks.

This timeframe ensures that your specific requirements are met, and the final product is delivered with the highest standards of quality.

At TGmold, we take great care in packaging each product to ensure it arrives in perfect condition. Our meticulous packing standards not only protect your components during transit but also reflect our commitment to delivering products with the utmost care and attention to detail.

Your satisfaction is our priority, and we ensure that every shipment is handled with the highest level of precision.

“Commit to a long-term partnership with Tiger Mold and unlock exclusive advantages—discounted pricing, faster lead times, and priority support. We’re here to ensure that our best customers always receive the best service and savings.”

Enjoy special pricing tailored for our long-term partners. As a VIP customer, you’ll receive exclusive discounts on every order, helping you reduce costs while maintaining the same high-quality products.

Stay ahead of your deadlines with priority shipping. Our VIP customers enjoy faster production and shipping times, ensuring your orders are always at the front of the line.

Never lose sight of your shipment. With our full order tracking service, you’ll receive real-time updates from production to delivery, giving you peace of mind every step of the way.

© 2024 Tiger Mold All rights reserved.

Your professional plastic mold parts manufacturer in China

Hello, this is Alva. Can I help you?

WhatsApp Us

🟢 Online | Privacy policy

We will contact you within 1 working day, please pay attention to the email with the suffix “@tigermold.com”.